What is Cooling Tower?

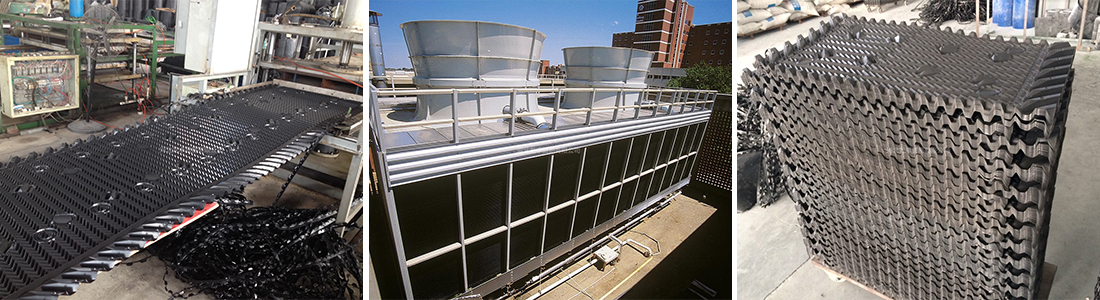

Maybe you are not familar with it,but most of the product we use-from the cloth we wear to the paper we use-it is indeed depend on them. More than 98% of potentially wasted water is recycled owe to cooling tower. Cooling Tower systems are heat rejection equipment that cool water to reduce the temperatures of industrial equipment that produces the products and the equipment that handles them. As core part in the cooling tower. Cooling tower fill is extremly important. It is made of Strong PVC material. Designed with textured patterns,usually ridges or wrinkles. The designer is very creative, so they creat S shape, W shape,and other beautiful shape. All the purpose is to increase the surface area of the tower Increased surface area allows for maximum contact between the air and the water, which allows for greater evaporation rates. so that when pieces of the fill are placed together they leave open spaces for water and air to travel. These spaces, called channels or flutes, are typically angled so that the water takes the longest possible time to travel their lengths. Individual pieces of fill are glued together to create blocks of fill which come in a variety of thicknesses and heights.

Cooling Tower

Selecting the right flute size is very important when designing a cooling tower. The smaller the flute size the higher the capacity per cubic foot, the less volume, and as a result lower costs. A marble sized flute would be more cost effective than a golf ball or baseball sized flute, and is this size is typically used in clean water application. So why use a larger sized flute? In dirty water applications, like steel mills, small flute fill would become clogged, or not work at all. A bigger, less effective fill is certainly preferable to a cooling tower that doesn’t work which is why choosing the most effective fill is vital for each cooling tower.

Longzhuo Manufacture a full types of cooling tower fills. To know more information,contact us freely!

评论

发表评论